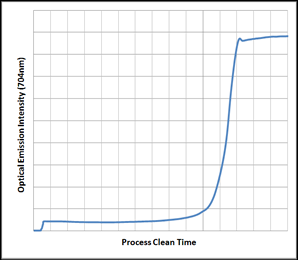

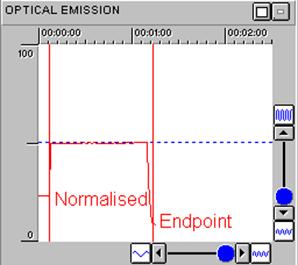

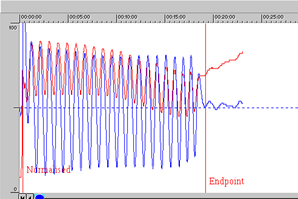

Endpoint detectors are an important tool for achieving optimal process results. Upgrade now and receive multiple benefits.

Endpoint detector upgrades currently available are:

Endpoint detectors are an important tool for achieving optimal process results.

Endpoint detectors are an important tool for achieving optimal process results.

公安机关备案号31010402003473

公安机关备案号31010402003473