materials such as , MoS2 or hBN can be used to enhance current devices and build new device architectures. FETs, batteries and filters with unique proporties can now be realised. Instruments Plasma Technology offers precise process control for mono/multi layer growth with defects.

Proven damage results.

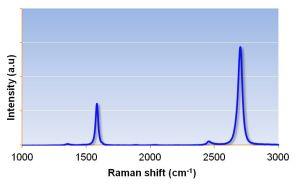

This specification is issued for obtained through Chemical Vapour Deposition (CVD) processes.

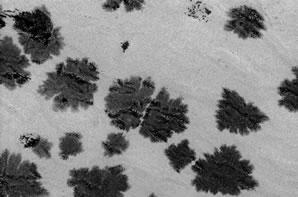

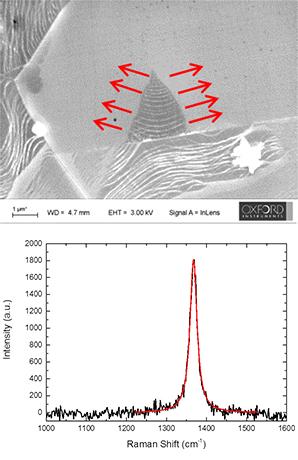

Direct growth of nanocrystalline on dielectric substrates using plasma enhanced chemical vapour deposition.

了解更多信息

了解更多信息

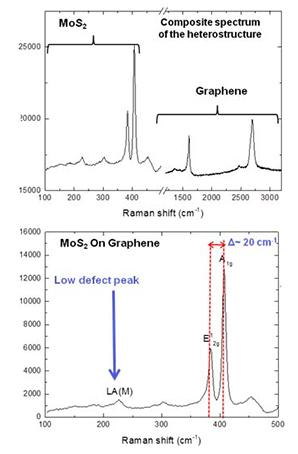

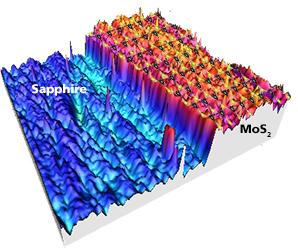

In situ growth of Molybdenum Disulphide (MoS2) heterostructures

We offer CVD/PECVD/Remote plasma (ICP) CVD systems equipped with precursor vapour delivery modules for the growth of two dimensional layers and heterostructures of materials like , MoS2, WS2 etc.

This is a three step process:

Process features:

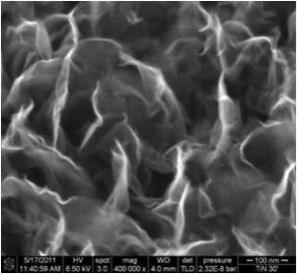

This specification is issued for Boron Nitride obtained through Chemical Vapour Deposition (CVD) processes. For the purpose of process demonstration, B2H6 is used as Boron source and NH3 as the Nitrogen sources on Cu/Ni foils as catalyst substrates.

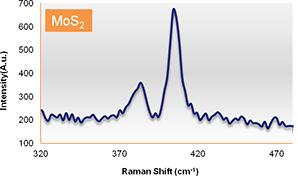

Growth of MoS2 and related Metal Dichalcogenides

We offer PECVD systems equipped with precursor vapour delivery modules for the growth of two dimensional layers of materials like MoS2, WS2 etc.

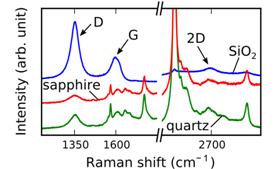

Excellent thickness control with defects and strong photoluminescence

quality MoS2:

公安机关备案号31010402003473

公安机关备案号31010402003473