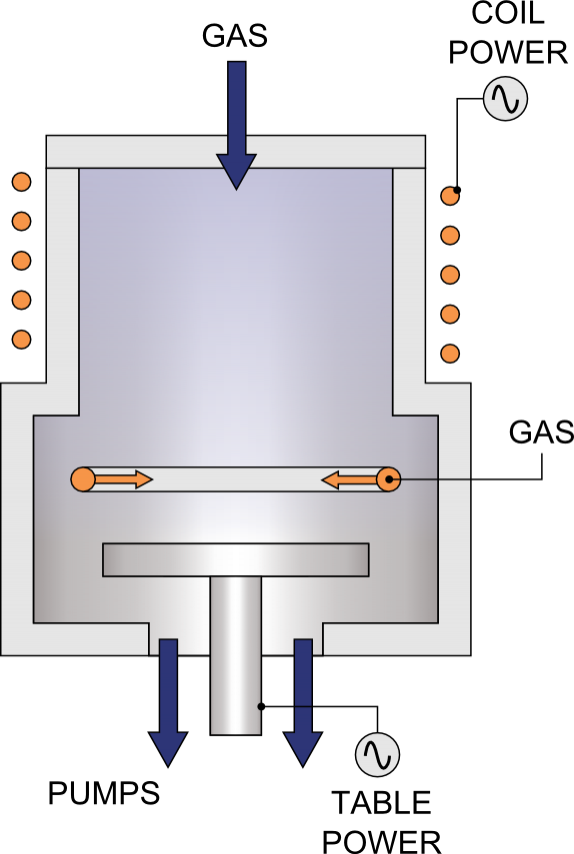

电感耦合等离子体源中高密度等离子体的产生意味着该技术能在低温下实现高质量低损伤的介质薄膜沉积。低温沉积意味着可以成功地处理温度敏感的薄膜和器件。

| PlasmaPro 80 | PlasmaPro 100 | ||

| Electrode size | 240mm | ||

| Wafer size | Up to 200mm | ||

| Loading | Open Load | Load locked or cassette | |

| Substrates | 50mm wafers | Up to 200mm with carriers options available for multi-wafers or small pieces | |

| Dopants | No | Various dopants available which include PH<sub>3</sub>, B<sub>2</sub>H<sub>6</sub>, GeH<sub>4</sub> | |

| Liquid precursors | No | ||

| MFC controlled gas lines | 8 or 12 line gas box available | ||

| Wafer stage temperature range | 20°C to 400°C | 0°C to 400°C | |

| In situ plasma clean | Yes | ||

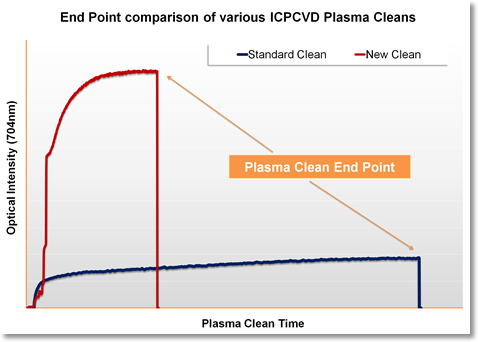

我们开发的ICPCVD等离子体清洗方案保证了在两次机械清洗之间的沉积重复性和减少了杂质颗粒。

系统利用率 > 70%

SF6/N2O混合气体

优化了的终点控制

等离子清洗可提升光学信号的强度,进而提高终点信号的强度/分辨率

所需的等离子清洗时间取决于沉积的薄膜材料、薄膜质量和薄膜厚度

公安机关备案号31010402003473

公安机关备案号31010402003473