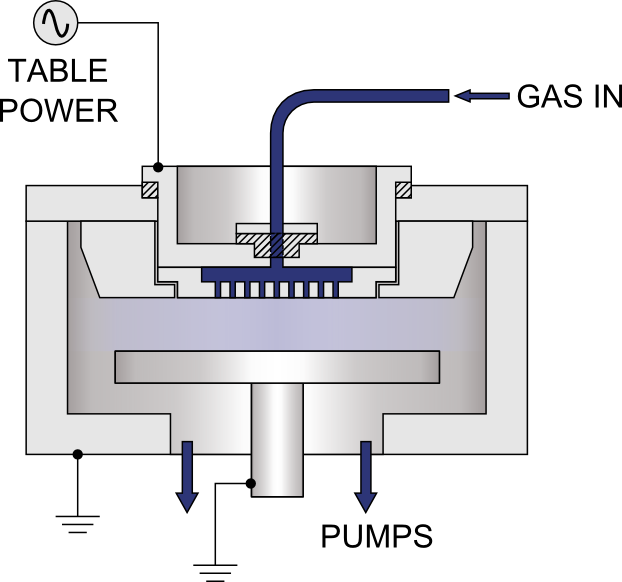

PECVD是一种应用广泛的薄膜沉积技术。许多类型的器件需要PECVD来制造高质量的钝化层或高密度掩膜。

我们的PECVD 系统专门设计用于生产均匀度极佳的高速薄膜,并可控制薄膜特性,如折射率、应力、电特性和湿化学蚀刻率。我们的等离子体清洗工艺具有终点控制功能,可消除或减少对物理/化学腔室清洗的需求。

| PlasmaPro 80 |

PlasmaPro 100 |

PlasmaPro 800 | |

| 电极尺寸 |

240mm | 460mm | 240mm |

| 衬底 | 直径可达240 mm,多晶圆或小片 | 直径可达200 mm,可选择多晶圆或小片载具 | 直径可达460 mm,多晶圆或小片 |

| 掺杂 | No | 提供多种掺杂剂,包括PH3、3B2 H6、GeH4 | No |

| 液体前驱体 | No | Yes (TEOS) | No |

| MFC控制的气路数量 | 可提供4、8或12条管路的气箱 | ||

| 用于应力控制的射频开关 | Yes | ||

| 晶圆台温度范围 | 20°C到400°C | 标准温度为20°C至400°C,可选温度高达1200°C | 标准温度为20°C至400°C |

| 原位等离子体清洁 | 是的,终点可用,以确保最佳清洁时间 | ||

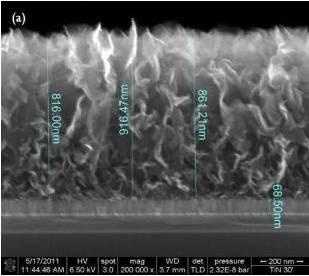

PECVD用于垂直排列石墨烯(比利时IMEC提供)

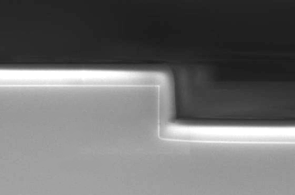

TEOS SiO2的PECVD

公安机关备案号31010402003473

公安机关备案号31010402003473