原子层沉积(Atomic Layer Deposition,ALD)是一种先进的沉积技术,允许以精确控制的方式沉积数纳米厚度的薄膜。ALD不仅提供了出色的厚度控制和均匀性,还能够对高长宽比结构进行全覆盖的包覆。

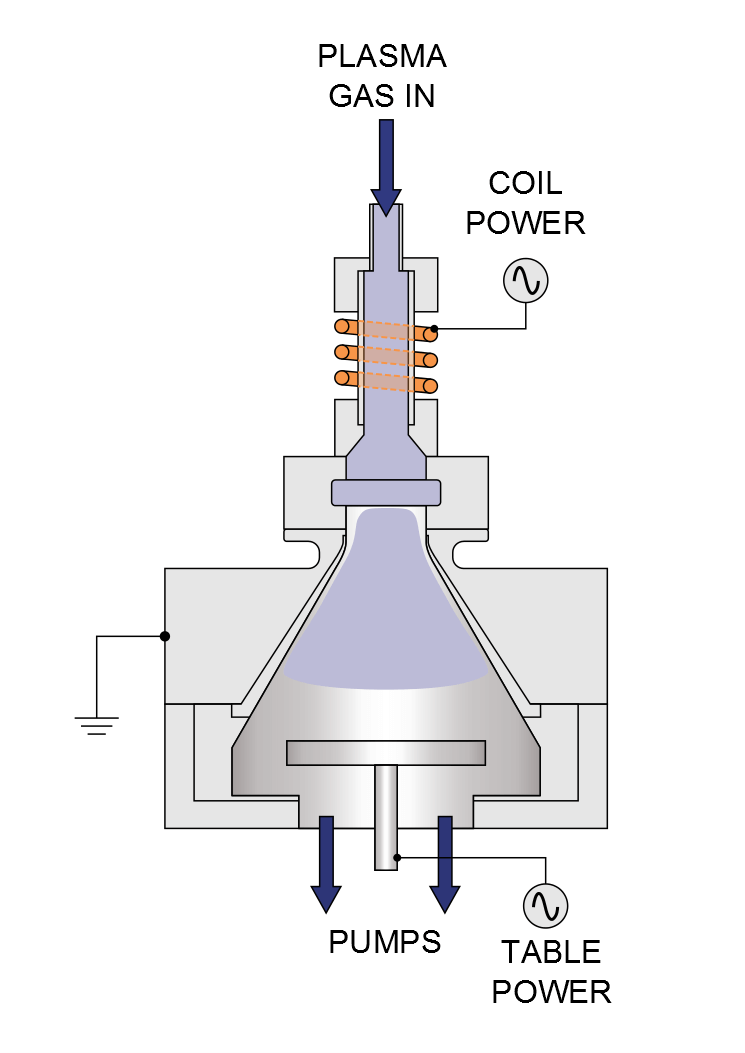

ALD依赖于自限制的表面反应,因此针孔和微粒含量通常很低,有利于广泛的应用。薄膜和界面控制水平以及所提供的高薄膜质量是许多应用所追求的。使用等离子体可以改善薄膜性能,控制薄膜,并使用多种材料。独特灵活的表面预处理可实现低损伤加工。

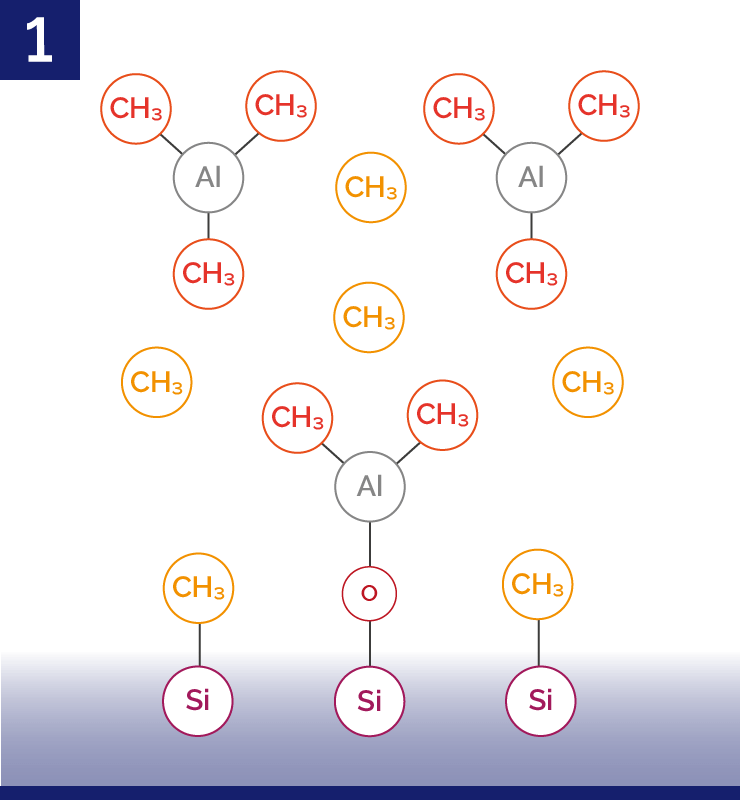

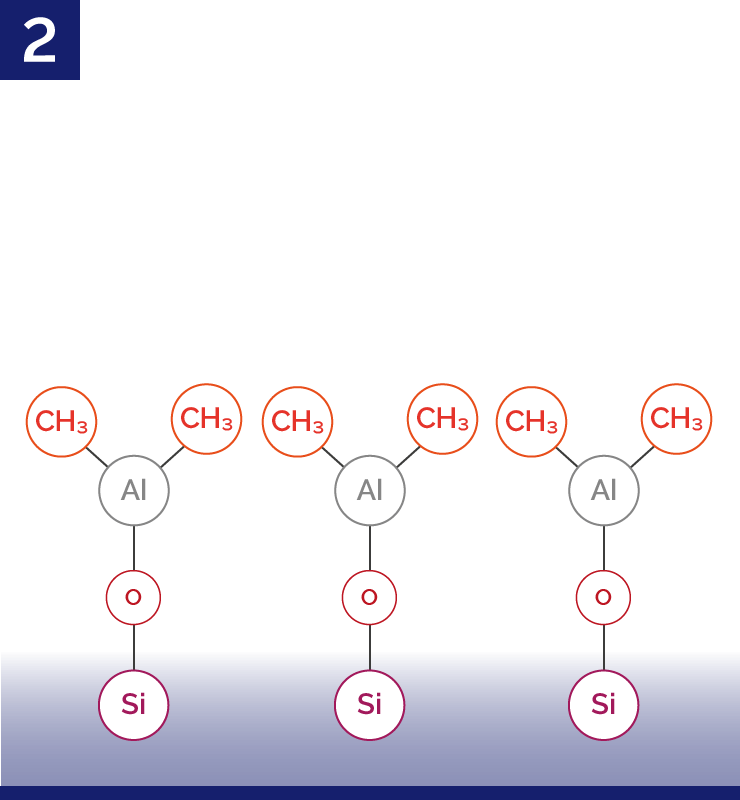

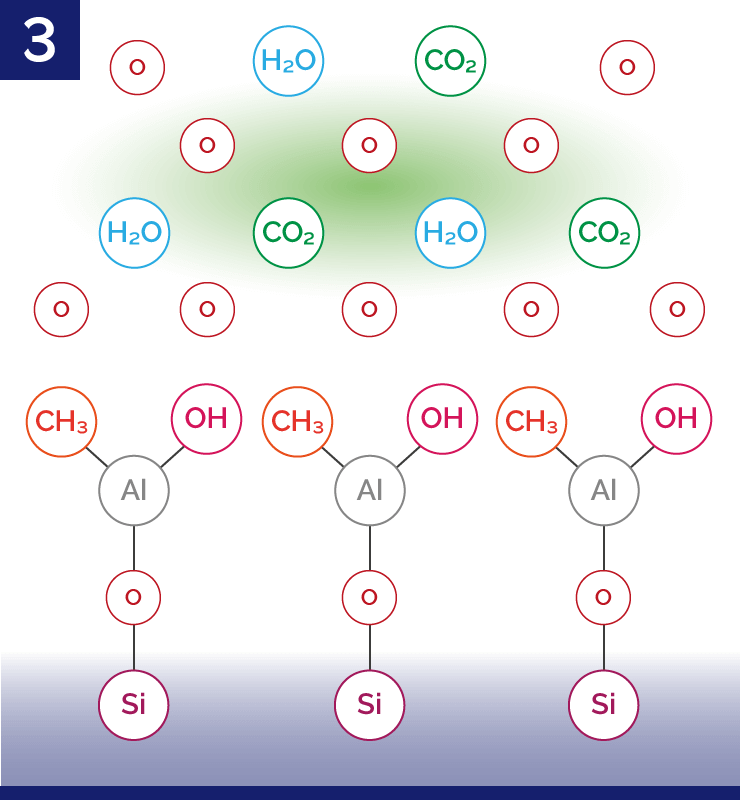

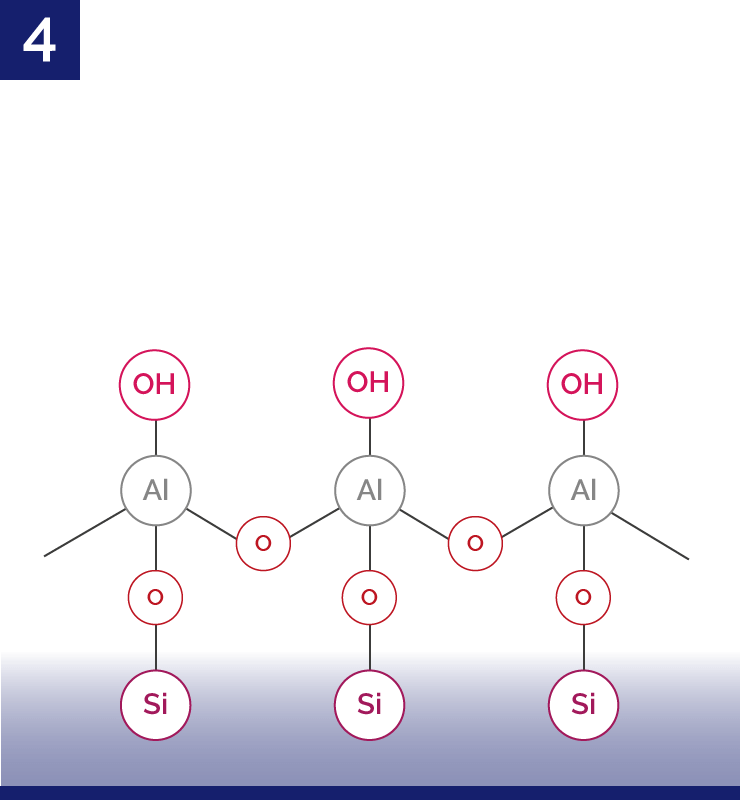

原子层沉积通常包括4个步骤的循环,根据需要重复多次,以达到所需的沉积厚度。以下是以Al2O3的ALD为例,使用了Al(CH3)(TMA)和 O2等前驱体物质。

步骤 1)在基底上添加TMA前驱体蒸汽,TMA 会吸附在基底表面并与之发生反应。通过选择适当的前驱体物质和参数,该反应会自限制。

步骤 2)清除所有残留的前驱体和反应产物。

步骤 3)使用活性氧自由基对表面进行低损伤远程等离子体照射,使表面氧化并去除表面配位体,由于表面配位体的数量有限,该反应也具有自限性。

步骤 4)清除室内的反应产物。

只有第3步在热处理工艺和等离子体工艺之间有所不同,热工艺过程使用H2O,而等离子体工艺使用O2等离子体。由于ALD过程每个周期沉积(亚)英格厚度的薄膜,因此可以在原子尺度上控制沉积过程。

1st Half-Cycle

Purge

2nd Half-Cycle

Purge

Al2O3, HfO2, SiO2, TiO2, SrTiO3, Ta2O5, Gd2O3, ZrO2, Ga2O3, V2O5, Co3O4, ZnO, ZnO:Al, ZnO:B, In2O3:H, WO3, MoO3, Nb2O5, NiO, MgO, RuO2

除了热ALD的优点之外,PEALD还能提供更广泛的前驱体化学选择,从而提高薄膜质量:

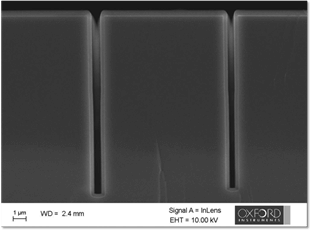

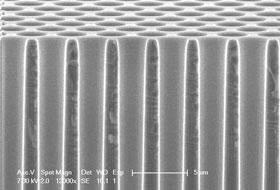

使用高速等离子体ALD SiO2对高长宽比(15:1)结构进行高度整形的涂层覆盖。

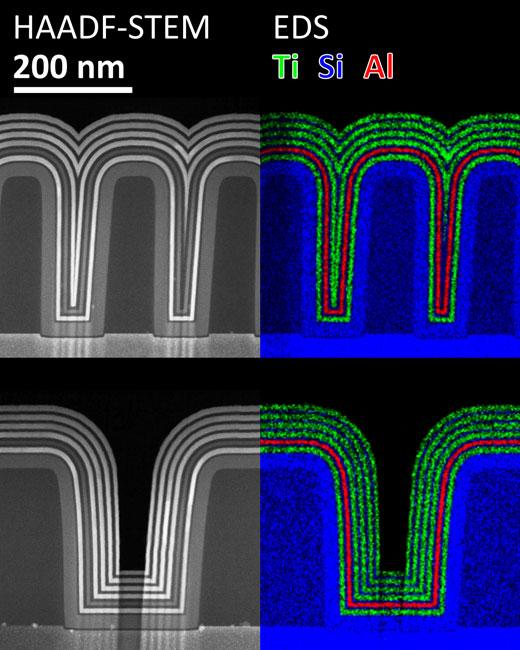

使用埃因霍温科技大学提供的FlexAL ALD沉积的Al2O3

等离子体ALD对SiO2, TiO2 and Al2O3的高度整形沉积,图片由www.AtomicLimits.com提供,采用CC BY 4.0许可证,出自2021年图像库。

| PlasmaPro ASP | FlexAL | Atomfab | |

| 装载方式 | 装载锁或盒式处理器 | 装载锁或盒式 |

盒式处理器。型号为Brooks MMX,它附带一个对准器。此外,还可以选择添加一个冷却站作为可选配置。 |

| 基底 | 处理最大直径为200 mm的晶圆和载板上的其他部件 | 处理最大直径为200 mm的晶圆和载板上的其他部件。 | 可以配置为适用于直径为200mm、150mm或100mm的晶圆的处理。 |

| 气泡化的液体&固体前驱体 | 多达6种前驱体,鼓泡或蒸汽吸取 | 多达8种前驱体,外加水、臭氧和气体 | 蒸汽吸取前驱体 |

| 最高前驱体源温度 | 最高200°C | 200ºC | 高蒸汽压前驱体冷却至室温以下,以进行可控和可重复的投放 |

| MFC控制的气体管道与快速投放系统;1)热气体前趋体(如 NH<sub>3</sub>, O<sub>2</sub>) 2) plasma gases (e.g. O<sub>2</sub>, N<sub>2</sub>, H<sub>2</sub>) | 设备上有4个可配置(有毒或无毒管路)线路气舱以及1个固定的氩气舱 | 最多 10 个外部安装的气舱 | 设备上有4个可配置(有毒或无毒管路)线路气舱以及1个固定的氩气舱 |

我们的原子层沉积设备拥有十多年的丰富经验。牛津仪器公司系统的主要特点包括:

原子层沉积技术可应用于多种材料,并且我们的工艺工程师可保证和设置多种工艺。对于新型工艺,我们丰富的工艺知识和庞大的网络使我们能够提供起点配方,这些配方应该是快速实现稳健工艺的良好起点。

通常,基于等离子体的工艺,可利用我们的等离子体知识和对MFC控制的气体混合物(包括有毒气体)的处理来提供。

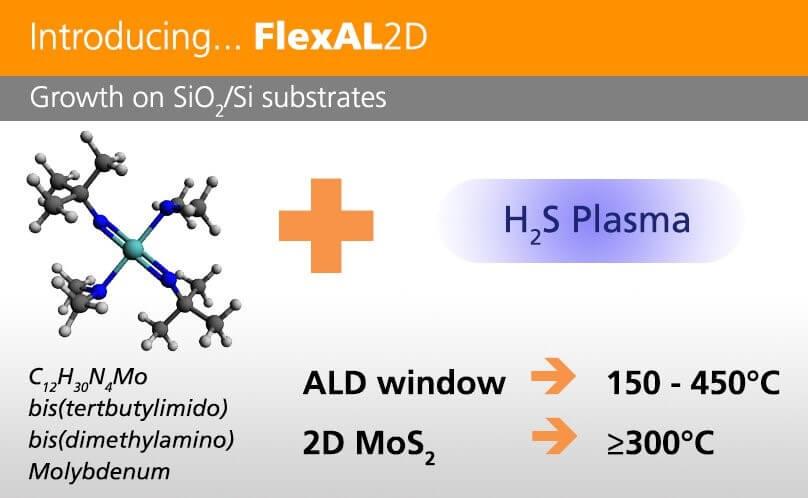

原子层沉积(ALD)也可以用于生长二维材料,这是一项新的发展,旨在实现高质量的MoS2薄膜。ALD的化学控制有望利用其在CMOS兼容温度下对大面积(200毫米晶圆)进行数字精确厚度控制的独特性质,以实现二维硫化物的应用。

金属 |

氟化物 |

硫化物 |

Pt |

AlF3 |

MoS2 |

Ru |

MgF2 |

氧化物 |

氮化物 |

Al2O3 |

AlN |

Co3O4 |

|

Ga2O3 |

GaN |

HfO2 |

HfN |

In2O3 |

|

Li2CO3 |

|

MoO3 |

|

Nb2O5 |

Nb2O5 |

NiO |

|

SiO2 |

SiO2 |

SnO2 |

|

Ta2O5 |

TaN |

TiO2 |

TiN |

WO3 |

WN |

ZnO |

|

ZrO2 |

我们很高兴为您介绍埃因霍温理工大学 (TU/e) 两名博士生的研究项目。作为工程科学和技术领域的领先大学,TU/e一直致力于创新工艺技术,旨在推动原子层沉积(ALD)这项先进的沉积技术在工业应用中的发展,该技术允许以原子级厚度控制沉积超薄薄膜。

牛津仪器等离子体技术公司与埃因霍温理工大学合作15年后,我们将继续推动ALD的研究和开发,这是纳米制造众多应用中发展最迅速的技术之一。两位研究学生Karsten Arts和Marc Merkx都使用了牛津仪器公司的FlexAL ALD系统,该系统配备了远程电感耦合等离子体源,可实现高质量沉积。

Atomfab是市场上速度最快的HVM远程等离子体ALD系统,专为制造GaN HEMT和射频(RF)器件而设计。

公安机关备案号31010402003473

公安机关备案号31010402003473